What is embodied carbon in construction? Everything but operating the building

The attention of the built environment is increasingly turning to embodied carbon as a key issue we need to address on our journey to net zero. But what is embodied carbon? And how can we reduce it?

Operational Carbon vs Embodied Carbon

Operational carbon refers to the carbon emissions associated with the energy used to operate a building – for example, the electricity needed to keep the lights on, or the gas used in the heating system. These emissions have traditionally taken centre stage in net zero discussions, and are improved by embracing renewable energy sources and reducing overall usage. They are important, but make up only part of a building’s carbon footprint across its full life cycle.

Embodied carbon refers to the remaining carbon emissions associated with the material extraction and manufacture, construction, maintenance, refurbishment, and demolition of a building.

Embodied carbon refers to the remaining carbon emissions associated with the material extraction and manufacture, construction, maintenance, refurbishment, and demolition of a building. For example, this includes the carbon emitted when steel beams are manufactured, transported, and then installed on site. Indeed, a significant amount of a building’s embodied carbon is emitted before it even begins to be used.

Learn more about the differences between operational and embodied carbon in our bitesize guides.

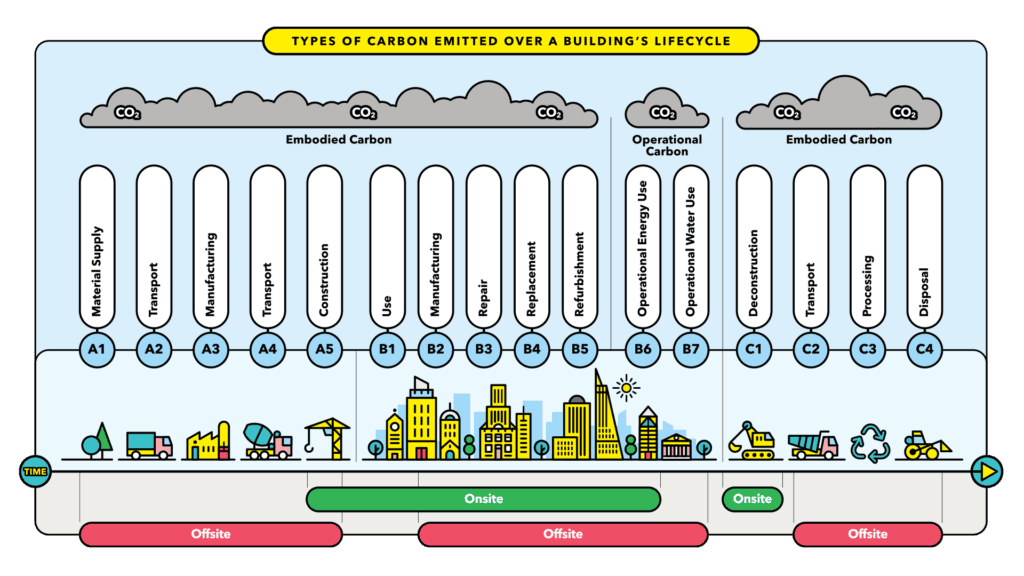

Embodied carbon at different life stages of a building

As embodied carbon covers such a broad range of activities, it has been broken down into three stages to make it easier to identify where these emissions need to be tackled.

Firstly, upfront embodied carbon refers to the emissions caused in production of materials and construction of the building before it can be used. In-use embodied carbon emissions cover the emissions associated with the materials and processes needed to maintain and refurbish the building whilst it’s in use. And finally, end-of-life embodied carbon refers to the carbon emissions associated with the demolition of a building and the transport, processing and disposal of that construction waste.

Learn more about Whole Life Carbon stages here.

Why is it important to reduce embodied carbon emissions?

Currently, embodied carbon makes up 20% of the UK built environment’s emissions. It is unregulated and is being reduced at a much slower rate compared to operational carbon. UKGBC’s Net Zero Whole Life Carbon Roadmap sets out the pathway for reducing these emissions by 2050.

However, since the Roadmap’s publication in 2021, industry is behind. Our recent Progress Report identified that embodied carbon emissions had fallen just 4% between 2018 and 2022 when they need to fall by 17% – this is compared to operational carbon that fell broadly in line with where it needed to.

Learn more about our pathway to net zero in the Whole Life Carbon Roadmap.

Having information easily available in a cohesive format provides a solid base for other industry professionals to make informed decisions

How can I reduce embodied carbon?

The importance of measuring & reporting

If we’re going to reduce embodied carbon as an industry, it’s important we accurately understand the level of emissions released by different materials, design choices, and processes. To achieve this, industry need to embrace modelling and reporting the embodied carbon of their developments, providing greater transparency and clarity across the industry.

Having information easily available in a cohesive format provides a solid base for other industry professionals to make informed decisions to reduce embodied carbon.

Learn more in UKGBC’s ‘Embodied Carbon: Improving your modelling and reporting’ guidance document.

Using less, and using low carbon materials

Many of the materials we traditionally use in construction such as steel, concrete and cement produce a lot of carbon during their manufacture, and indeed emissions from materials form a significant part of a building’s entire embodied carbon. In the first instance, we should design buildings to use fewer materials – especially fewer carbon intensive materials. After a building has been designed to use less, the materials that are needed should be low carbon wherever possible.

Common low carbon materials:

- Bio-based, or biogenic, materials have reduced carbon emissions due to the carbon they sequester during their growing lifetime. For example, using timber for a structure instead of steel reduces the embodied carbon considerably.

- Reused materials reclaimed from the built environment as part of the circular economy. For example, reusing steel can have a 97.5% lower embodied carbon than new steel.

- Innovations within material production have also produced lower carbon alternatives that use recycled elements or reduce material needed through careful design.

Learn more about resource use and the circular economy, and how it can reduce our carbon emissions.

Retrofit

One of the most effective ways to reduce embodied carbon is to retrofit a building instead of demolishing it and rebuilding from new. By retaining the original structure much of the carbon emissions can be saved in the upfront stage of a building’s life. The deep retrofit of The Entopia Building in Cambridge saved around 60% of the embodied carbon compared to demolition and rebuilding the structure. Even partial reuse by retaining a façade or core structure can mean the embodied carbon on a project can be significantly reduced. During the retrofit of 1 Triton Square the refurbishment of the façade saved 2,400tCO2 compared to a new façade.

The need for better policy

The government needs to bring in legislation that prioritises the reduction of embodied carbon, which is currently unregulated. UKGBC is calling for:

- The mandatory measurement and reporting of whole life carbon (combination of both operational and embodied carbon) for new buildings and major refurbishments – starting with large buildings and residential developments.

- Planning policy to be reformed so that the reuse of existing buildings is prioritised over demolition.

- Limits for upfront embodied carbon on buildings should be introduced, with associated financial incentives to assist industry in the transition to lower carbon alternatives.

What is UKGBC doing on embodied carbon?

UKGBC is committed to working with industry to create best-practice guidance and amplify solutions for reducing embodied carbon within our built environment.

Most recently, we launched, ‘Embodied Carbon: Scope 3 Measurement & Reporting’ to support industry professionals as they look to streamline their scope 3 and embodied carbon reporting. This followed on from our ‘Embodied Carbon: Modelling & Reporting’ guidance document launched in 2023 that outlines how we can build consistency and transparency in reporting across the sector.

If you want to learn more about UKGBC’s ongoing work, you can get in contact with our Advancing Net Zero team here.

Related

UKGBC joins industry leaders calling for Government to regulate embodied carbon

Transparent embodied carbon reporting is key to delivering sustainable construction

Circular development and net zero construction: a commercial office in the heart of Edinburgh

Beyond the building: reducing embodied carbon through innovative master planning