Manufactured limestone aggregate for low carbon construction

Problem Addressed

How to reduce the use of virgin aggregate and safeguard natural resources through a Carbon Capture and Utilisation (CCU) Process – permanently capturing significant volumes of carbon dioxide.

Case Study

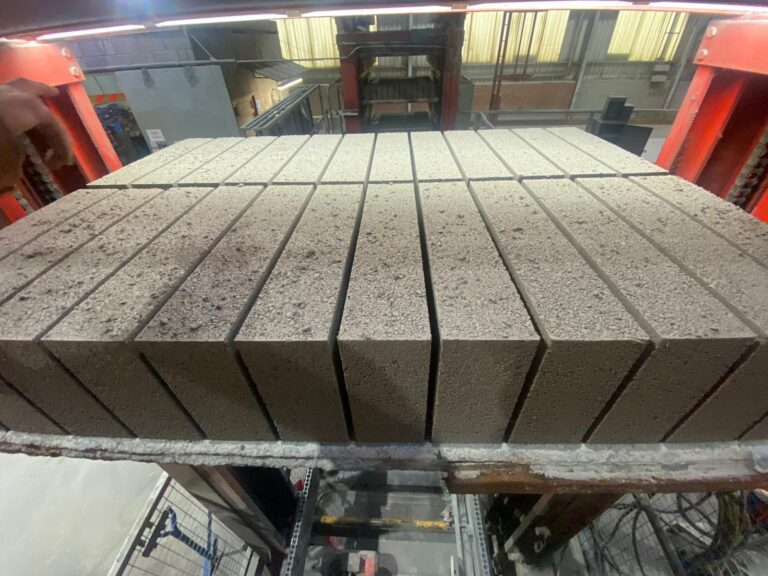

Two of the UK’s largest block manufacturers use the M-LS Block mix product in their medium dense blocks as well as some independent block makers. This has seen a total of 21 million blocks produced in the UK with our product which equates to 8,000 three-bedroom houses. Some of the biggest producers of aggregates are utilising our product in Type 1 as it protects their reserves and the finished product gives durability, strength and compactability as well as having the all-important green credentials.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Sensors and AI to predict concrete curing time

Decarbonising Precast Concrete

Cement alternatives

Cement made from recycled waste