Decarbonising Precast Concrete

Problem Addressed

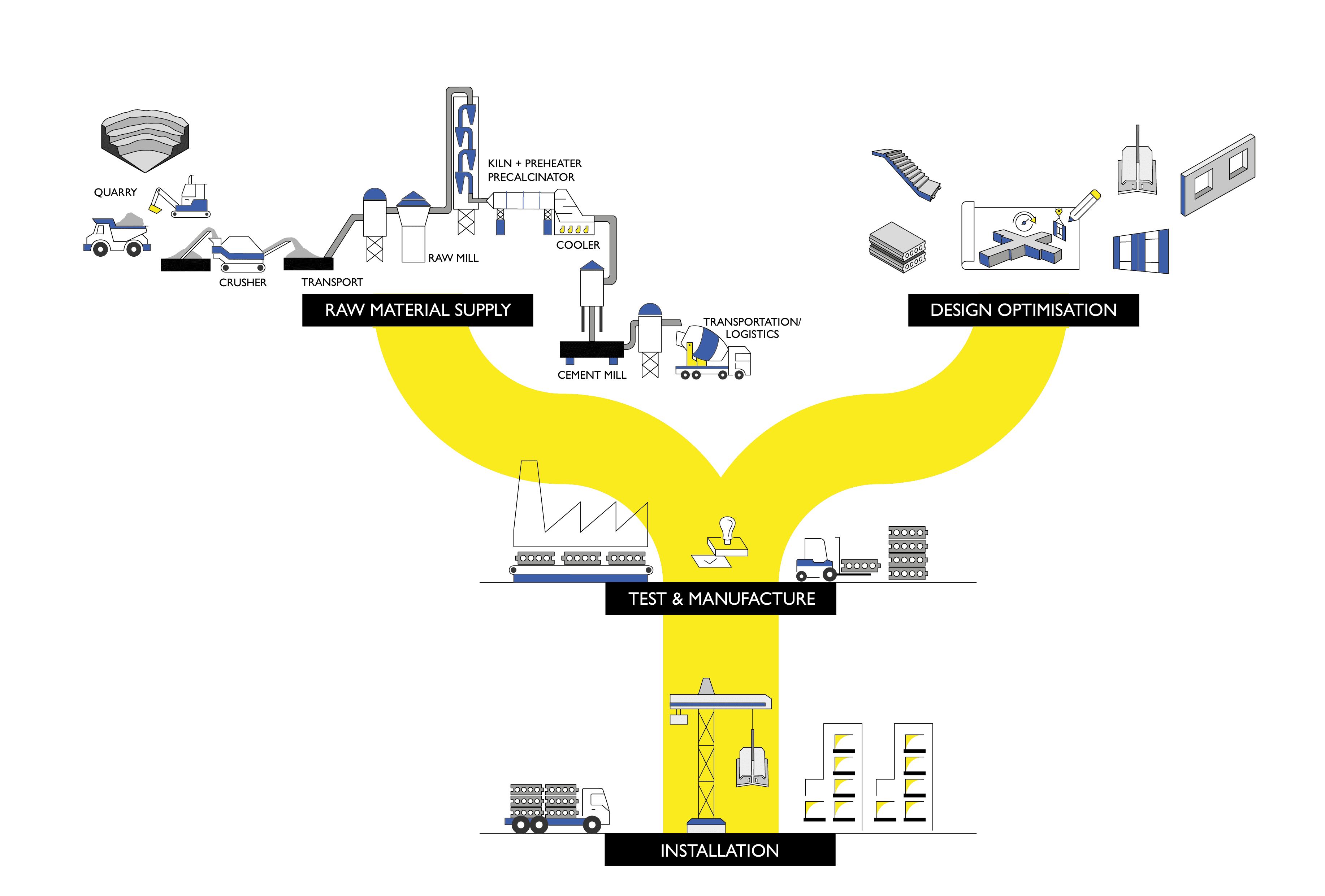

Precast is one of the most widely adopted Modern Methods of Construction (MMC), however as a cement-based product, concrete manufacture is a fuel and electro-intensive process, said to be responsible for 4-8% of the world’s CO2 emissions, according to Akerlof.

The Industrial Decarbonisation and Energy Efficiency Roadmap to 2050 exposed an urgent need for UK cement manufacturing to become more resource, energy and carbon efficient, outlining an action plan for Government and industry to pull together to ensure decarbonisation is achieved, cost-effectively. Significant barriers exist however, on both supply and demand sides (not least cost and knowledge gaps) limiting their application to date.

The UK’s first carbon-neutral cement was launched 3 years ago yet adoption and relevant application opportunities are low, with clients, specifiers and contractors cautious of novel building materials. In addition, research by Chatham House identifies the majority of products have failed to achieve commercial viability.

In an industry challenged to reinvent and address strategic priorities, such as net zero carbon, business survival is a priority. The Minerals Product Association (MPA) has expressed the need to develop solutions that are technically feasible and economically viable, maintaining the competitiveness of domestic manufacturers. However, increased demand for products and market growth, stimulated as a result of COVID, without corresponding innovation, could represent a threat to the clean growth strategy of the UK.

Case Study

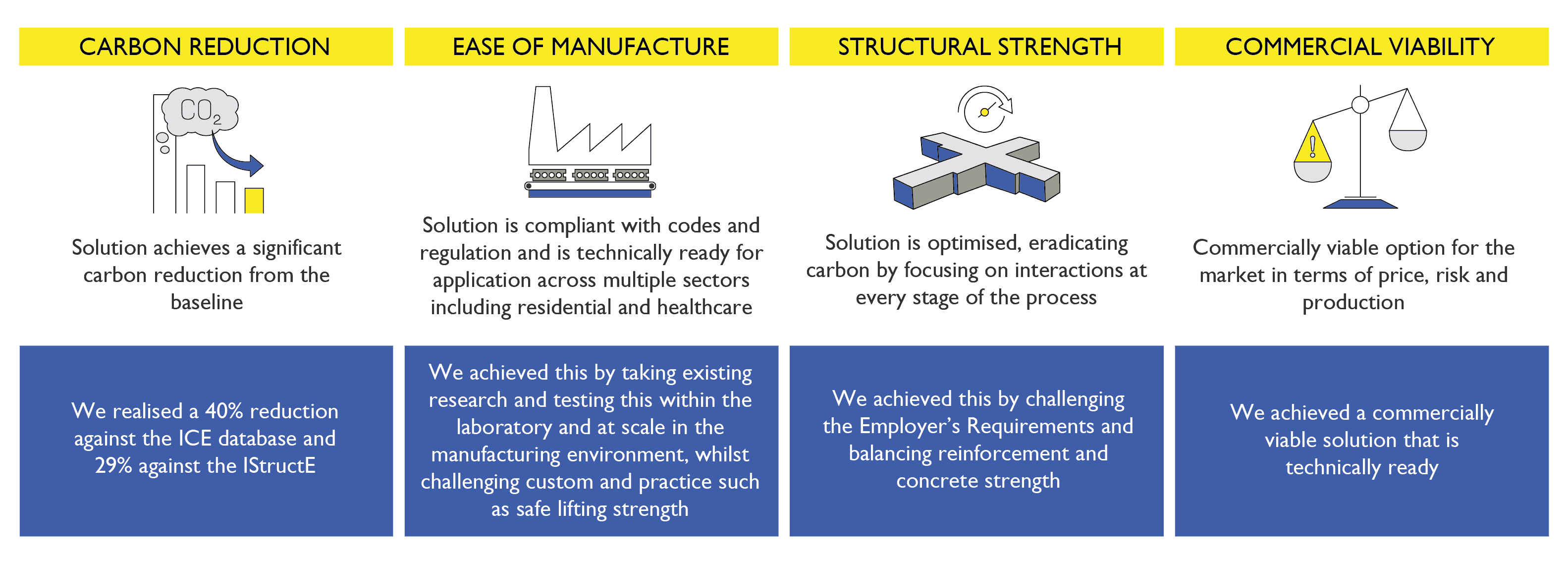

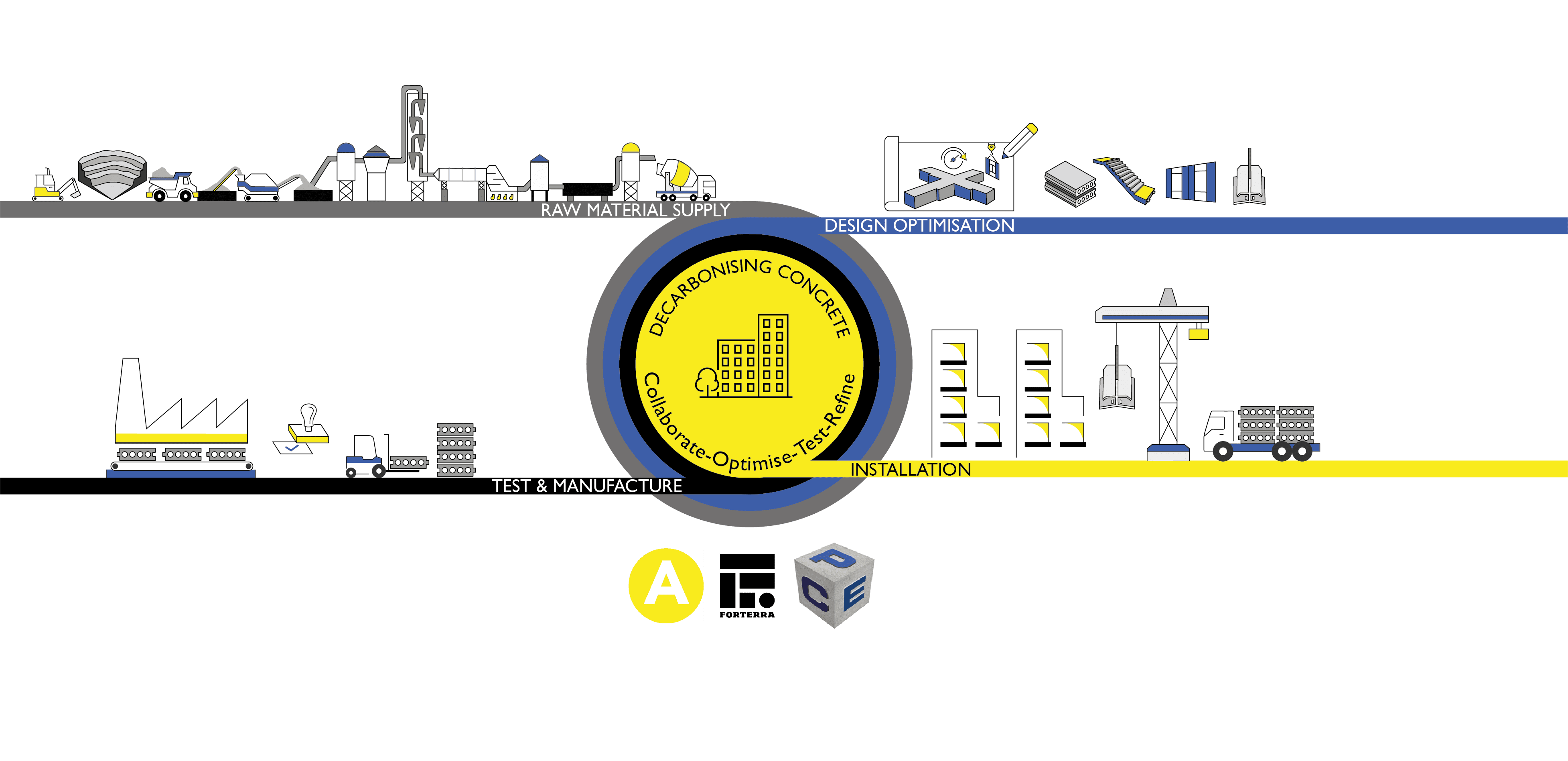

The team ensured the solution was commercially viable and technically ready for adoption by companies across the sector, in the immediate. The solution is now being rolled out across the £2bn ‘4 New Prisons’ Programme for the Ministry of Justice. “This study demonstrates how collaboration through the supply chain can bring subject matter experts together to develop innovative solutions for decarbonising. We look forward to utilising and embedding such solutions in the Ministry of Justice’s New Prison Programme.’’ Gareth Jones Head of MMC & Technical Services, Ministry of Justice

Read the full case study and video here: https://akerlof.co.uk/decarbonising-concrete

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Sensors and AI to predict concrete curing time

Zero cement concrete

3D printed concrete beams designed to use less material

3D printing optimised structures using less concrete