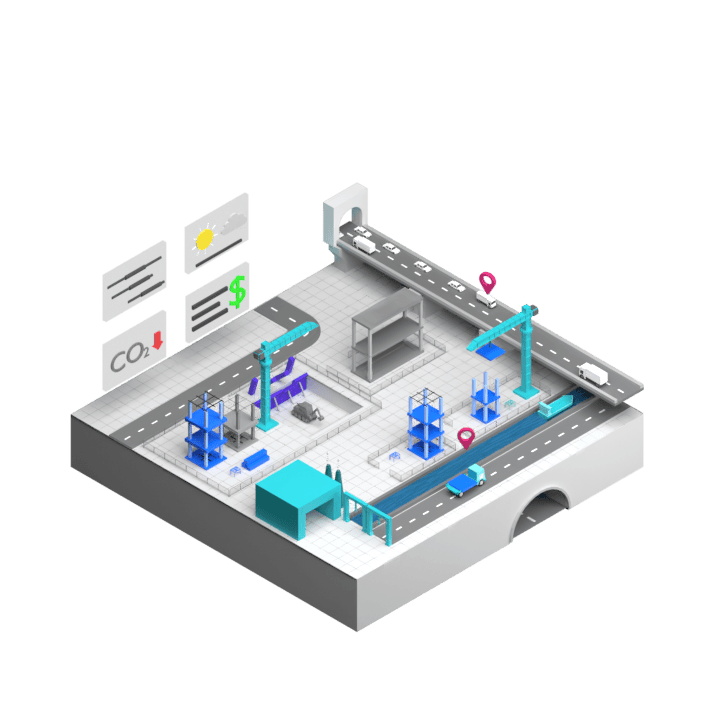

3D printing optimised structures using less concrete

Problem Addressed

In the built environment, cement use is the cause of 8% of global CO2 emissions every year, according to the BBC. Construction companies face the challenge of virgin material over-consumption, whilst industrial companies endure high storage costs and high risk environments from the generation of large quantities of waste.

Case Study

Hyperion Robotics designed and produced 2 x 2 m water tanks for the mining industry made with almost 99% recycled mining tailings and zero cement.

Metso Outotec develops mineral processing plants for mining and industrial companies that allow the drying of mining tailings on a very large scale. Once the tailings are processed, Hyperion Robotics’ solution is used to complement Metso’s technology, allowing the use of a high percentage of this waste as a component in their concrete. The concrete has been used to produce sustainable infrastructure products for the mining company itself, but also for the surrounding communities. They are currently looking into building similar tanks with 10 x 10 m dimensions.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

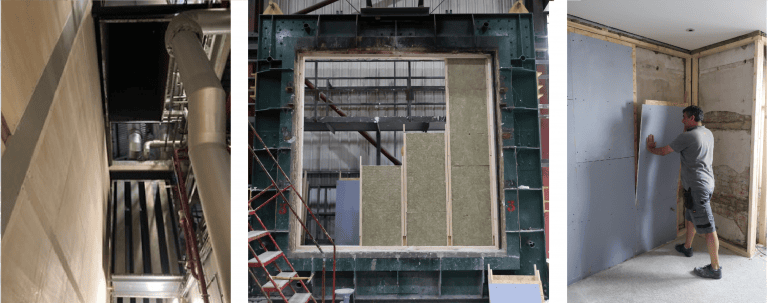

Acoustic modular wall system eliminating waste

Sensors and AI to predict concrete curing time

Zero cement concrete

Decarbonising Precast Concrete