Acoustic modular wall system eliminating waste

Problem Addressed

Construction waste.

According to DEFRA’s February 2018 edition of UK Statistics on Waste, in 2014 the UK generated 202.8 million tonnes of waste, and construction, demolition and excavation was responsible for 59% of that number (NBS).

The environmental and commercial arguments for mitigating such profligacy are clear, and one significant solution lies in a relatively simple concept – materials resource efficiency.

WRAP UK, in their document ‘Designing out Waste: A design team guide for building’, state the following: “Using materials more efficiently is a highly effective sustainability strategy and involves a balanced approach, ensuring that at each stage of construction materials are used in an efficient manner.”

WRAP UK identify, in this document, the crucial contribution designers can make in reducing waste through their design and present five key principles to guide them, accordingly:

- Design for Reuse and Recovery

- Design for Off-Site Construction

- Design for Materials Optimisation

- Design for Waste Efficient Procurement

- Design for Deconstruction and Flexibility

Case Study

ENGIE’s ExCEl District Energy Centre provides heat and power to the ExCel Exhibition Centre and surrounding area (London’s Royal Docks), using Combined Heat & Power engines (CHPs). Airborne sound, emanating from these engines, was the cause of continuous noise nuisance complaints from the adjoining dwelling-apartments. Akustak® was specified to mitigate the problem, from the Energy Centre side.

Its modular construction and manoeuvrability (particularly at height and within confined spaces) made Akustak® a good fit for this logistically challenging project. The modules were modified to suit the rigours of an industrial environment, including a fire-treated, impact resistant fascia; ensuring the installation is fit-for-purpose, for years to come.

Pre-completion sound insulation testing demonstrated that, following the Akustak® installation, sound levels in the adjoining dwelling-apartments, due to the transmission of Energy Centre sound, met World Health Organisation (WHO) limits, i.e. in bedrooms at night (23:00 to 07:00), the guidance limit is 30 dB LAeq, 8h and for living rooms and bedrooms during the day, the guidance limit is 35 dB LAeq, 16h.

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Flexible building system for a zero carbon building

OKIBO

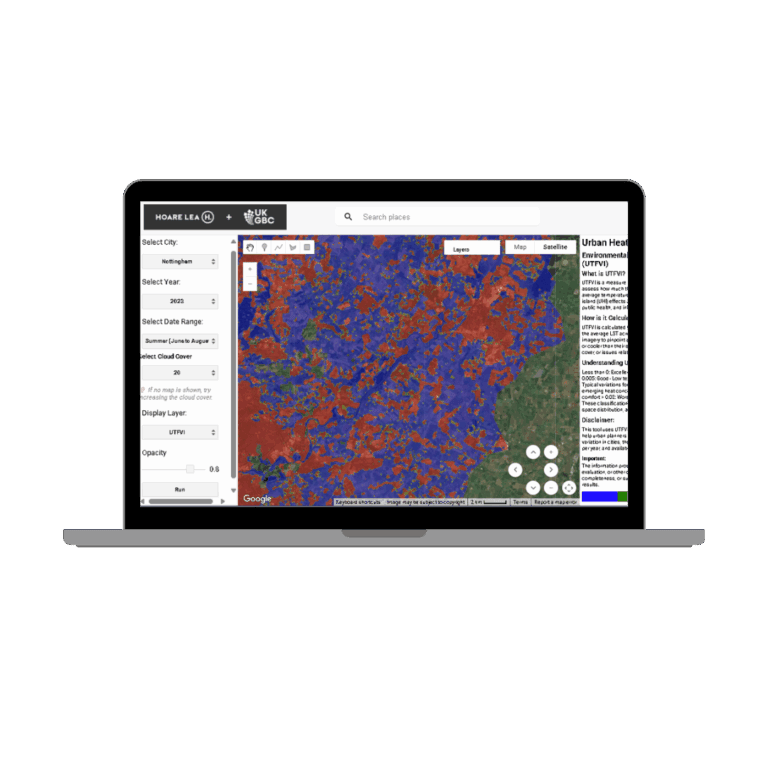

Urban Heat Island Web Map

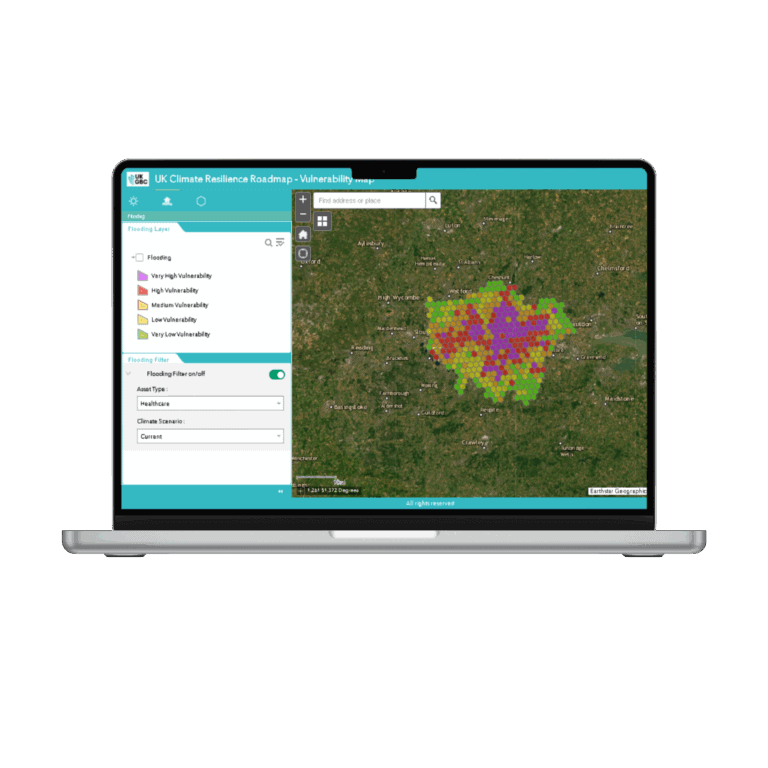

GIS Vulnerability Web Map