Cement

Cement is a fine powder made from a mixture of limestone, clay, and other minerals, which is commonly used as a binder together with aggregates to make concrete. There are various types of cement, such as Portland cement, slag cement, and fly ash cement, each with different properties and uses.

A key ingredient of cement is clinker, which is produced by heating limestone with other materials such as clay and shale, a process that releases large volumes of C02, which makes cement responsible for 8% of global carbon emissions. Limestone is a sedimentary rock mainly consisting of calcium carbonate because of its chemical composition, it is likely to form karsts and caves that provide unique habitats.

Cement is manufactured from raw materials extracted globally, however, in the UK we mostly use cement from materials extracted from the UK.

Material Extraction

- Quarrying of limestone and clay from open-pits by blasting and mechanical crushing.

Key Impacts

Habitat destruction

Sedimentation and Erosion

Existing safeguards and certifications

- Planning system. Potential new quarrying sites will require planning permission within the UK, including an Environmental Impact Assessment and ecological surveys which assess ecological impacts comprehensively before extraction. It must also include a plan for remediation at the end of the extraction period.

Best practice and recommendations

Explainer

Secondary binders are waste products from other industrial processes such as fly ash from coal combustion, or slag from iron blast furnaces. This increases the efficiency of using our resources but is limited to the availability and capacity of the other process which itself come with ecological impacts that need to be addressed.

Many of the available binders are globally constrained and should not be specified exceeding their availability. More abundant binders include volcanic rocks and calcined clays. Industry should explore opportunities for biobased cement alternatives.

Solutions

- Renaturation of quarries. Applying principles of restoration ecology to mined areas helps rehabilitate or even enhance landscapes post-extraction and restore biodiversity and ecosystem functions. This has resulted in many protected sites, such as Sites of Specific Scientific Interest (SSSI) and nature reserves, across the UK.

- Bio-based cement alternatives. These materials are currently being explored in research in pilot projects, such as cement-like materials that use micro-algae to bind mineral materials together to create new bio-composite materials.

Summary

Cement is a high–impact material that is widely used in the industry. While some alternatives exist, they mostly come with their own ecological impacts, or a limited in supply for widespread adoption worldwide. Prioritising existing assets in line with the resource use mitigation hierarchy is key.

Industry Solutions

Extraction and Biodiversity in Limestone Areas

Explore this report that outlines the biodiversity of limestone rich areas and how they are vulnerable to damage, as well as more information on practical solutions for making biodiversity & extraction compatible.

Explore solutions in UKGBC’s Library

Cement made from recycled waste

Cement alternatives

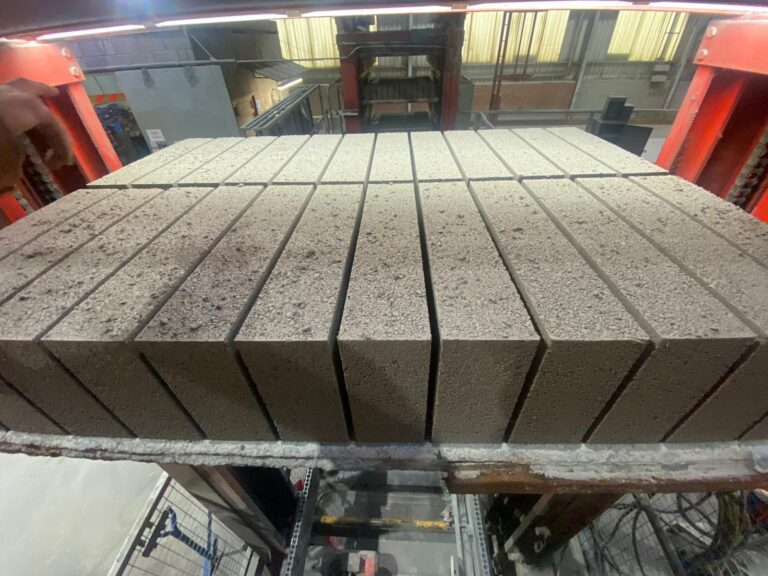

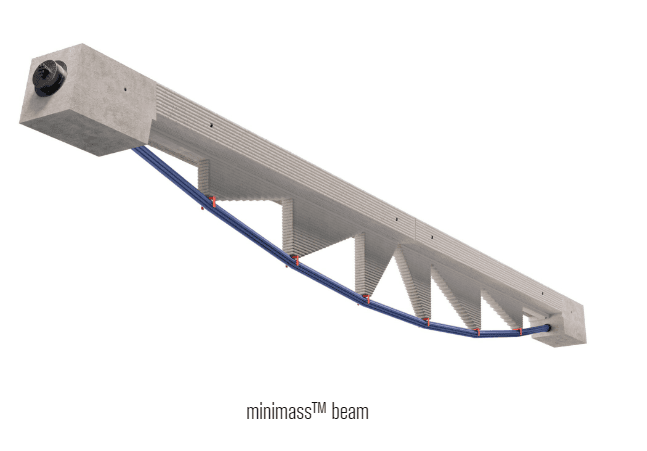

3D printed concrete beams designed to use less material

Zero cement concrete

Foamed Asphalt Incorporating Manufactured Limestone

Eliminating structural concrete overdesign with AI

Decarbonising Precast Concrete

3D printing optimised structures using less concrete

Explore other materials

Aluminium

Aluminium ore, or Bauxite, is the raw material used for the production of aluminium, which is extensively used in construction for its anti-corrosive and lightweight properties. It is applied as a lightweight and structural material, for example in window and door frames, roofing, and cladding.

Aggregates

Globally, almost half (46%) of all primary aggregates are used to manufacture concrete and cement. Just over a quarter is used in roads and 2% is used for railway ballast. The rest is used to provide drainage, fill voids, protect pipes, provide hard surfaces, and in water filtration and sewage treatment processes.

Iron Ore

Iron ore is a natural mineral deposit that contains iron in various concentrations and is the raw material for the production of steel. It is the world’s most extracted metal and the basis for the production of steel, one of the biggest commodities worldwide.

Timber

As a renewable material with the ability to sequester carbon, the interest in timber has surged in our industry. The majority is used as sawn softwood and boards, while 1 percent is used to produce glue-laminated timber (Glulam) for load bearing elements such as rafters, or cross-laminated timber (CLT) for surfaces such as walls and floors.