Intelligent building vibration reduction system

Problem Addressed

Structural vibrations in buildings are a critical problem for today’s construction industry. These vibrations can be disruptive, cause discomfort to occupants, and even accelerate structural wear and tear over time. Currently, floors must be made stiffer and heavier to provide satisfactory vibration reduction, but this comes with additional costs and embodied carbon.

Case Study

CALMFLOOR was used in an existing office floor set in a London mixed-use commercial building which had experienced issue with floor vibration. The units were installed on the customer’s floor, minimising the need for disruption and required no structural modifications. Strategic positions were chosen as vibration hot-spots, and once installed, the active mass damping technology resulted in nearly a 75% reduction in vibration responses.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related members

Related

Wet heating system deaerator

Technology to adapt room temperature based on occupancy levels

Smart fused spurs to reduce device energy use

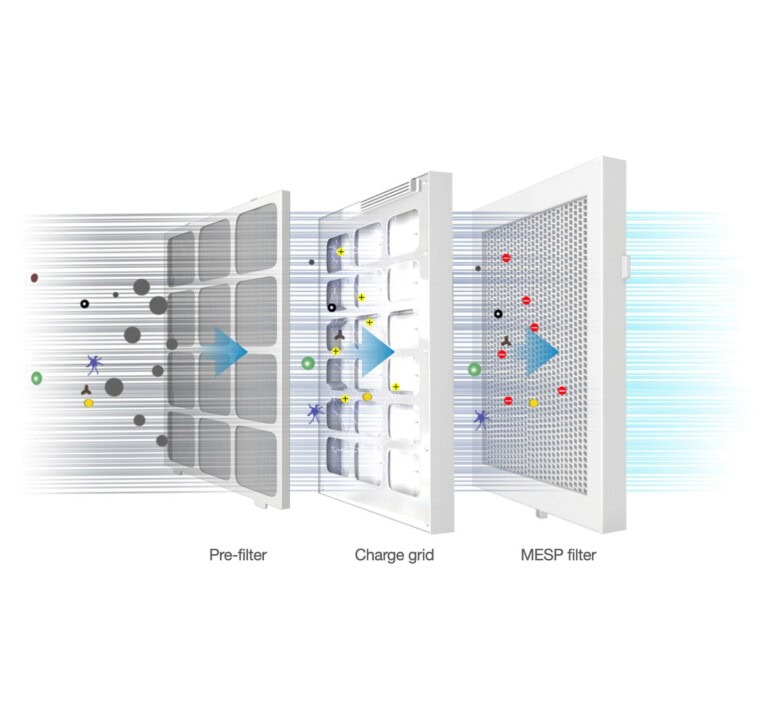

HVAC Filter Using Micro-Electrostatic Precipitation