Holbein Gardens

Key Sustainability Objectives/ Outcomes

- Aligned with the UKGBC’s Net Zero Carbon Buildings: A Framework Definition.

- Acting as a LETI Pioneer Project.

- Aligned to NABERS methodology.

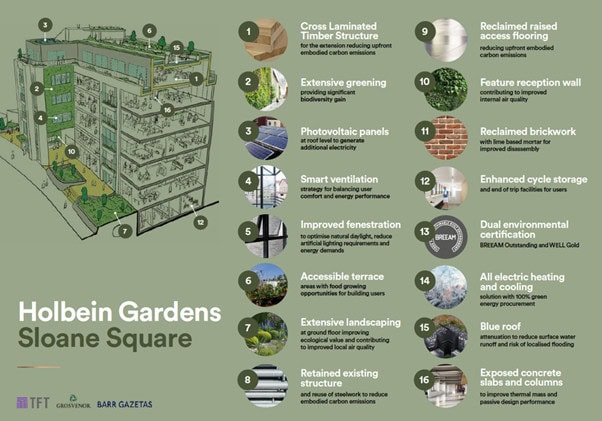

- Targeting BREEAM Outstanding, WELL Gold and Wired Score Gold certifications.

* This project is included in the “How circular principles impact Carbon and Value” report.

Notable Approaches And Solutions

- The brickwork has been designed for deconstruction with new bricks being assembled using lime mortar which can be cleaned off at end of life, enabling the bricks to be reused. The Lime culture is estimated to have 20% less CO2 emissions than cement manufacturing and will absorb CO2 over the hydration process, meaning over time it will become carbon neutral. (2d)*

- The steelwork is also designed with mechanical fixings so it can be deconstructed at end of life. (2d)*

- Cross Laminated Timber is being used for the roof extension Which is also assembled with bolted connections to allow for deconstruction (2d). However this can be more expensive but was offset by comparative advantage on programme and sustainability credentials.*

- CEMFREE concrete: can save up to 80% embodied carbon compared with conventional concrete mixes.* But there can be a potential cost uplift depending on the element and an impact on programme time due to longer curing period.

- Thermalite aircrete blockwork.

- Reclaimed raised access flooring, feeding into our wider re-use network.

- Anti-bacterial and air-purifying tiles in toilets.

- A conscious decision was taken to retain and refurbish the existing building for environmental reasons. However, the Reuse of the original structure has meant that the flexibility of the building has been impacted. If the building was demolished and rebuilt, there would have been the opportunity to have a larger floorplate which would have a created a more flexible product long term. (2b) *

The use of Circular Principles and other measures to reduce the embodied carbon will reduce the level of carbon offsetting once the project is complete. This could offset some of the price uplifts seen from some of the other innovative approaches taken on this project.

Lessons Learnt

When repurposing materials between existing development projects including Holbein Gardens we discovered a gap in industry knowledge and networks for the re-use of materials more broadly. To overcome this, in 2021 we canvassed 120 built environment professionals, representing the full lifecycle of a building, to find out more about the prevalence of, and barriers to, accelerating material re-use. The results were showcased through a series of educational webinars and supported the creation of a re-use network which now has over 700 active participants who can request or advertise specific materials. We are also working closely with industry forums such as SteelZero, of which we are a founding member, to further support the transition towards net-zero steel and material re-use including addressing the challenges associated with procuring low-embodied carbon steel and implementing steel re-use.

- There was an original ambition to use recovered bricks for the façade, but there were quality issues which meant they could not be used; the challenge with reused items is that the quality is not assured for the scale needed on this type of project*

- The reused steel was more expensive due to the cost of extraction from the old site and the transportation for testing before they could be reused *

Availability of data is improving, but product EPDs do not always have complete info which can impact carbon reporting. *

Related

11-21 Canal Reach – Meta Office

1 Triton Square

55 Great Suffolk Street

Roots in the Sky