Flue Gas Recovery Technology

Problem Addressed

UKGBC’s Whole Life Carbon Roadmap supports a gas boiler phase-out and including an end to the sale of gas boilers by 2030. However, reducing the carbon emissions and improving the energy efficiency of the existing boilers is an imperative during this transition. As hot water boilers can generate a significant amount of heat, capturing and reusing this heat is an important way to maximise their effectiveness during their phase-out.

Case Study

Carbon Cap’s early technology development was federally funded thereby requiring comprehensive and certified energy and environmental impact reports that included its demonstration in a live building supported by significant benchmark data.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Wet heating system deaerator

Smart Hot Water Cylinder

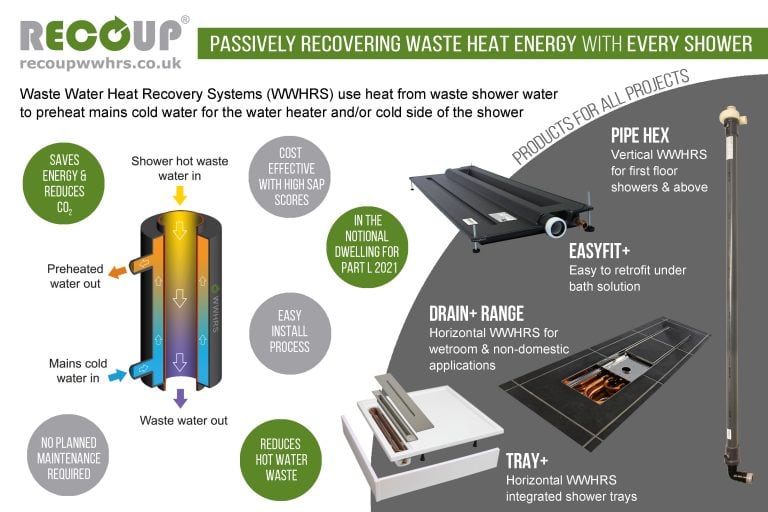

Waste water heat recovery system for showers

Smart radiator control