Materials Passports Platforms

Problem Addressed

61% of waste comes from construction, demolition, and excavation, much of which could be recovered and reused. Materials Passports act as identity cards for materials and products and can reduce waste by storing key information over their life-cycle. This information can also support reporting requirements, assist in the maintenance of the materials, and offer options for material recovery and reuse at end-of-life.

The table below includes information about many of the solutions in this area with information provided by the solution provider. Please click on the company names to see more information about each solution.

| Company name | Upcyclea | Madaster | Circuland |

|---|---|---|---|

| Data included | Physical and technical, manufacturer, health and safety, warranty, EPDs/sustainability, end-of-life options, next lives options, amount of recycled materials, amount of biobased material, material/component composition, version number, manufacturing locations, reliability rating, indexes compatible with AI-based algorithms to connect with needs in reuse/recycling/upcycling | Physical and technical, manufacturer, health and safety, warranty, EPDs/sustainability, reuse, end-of-life, detachability, amount of recycled materials, amount of bio-based material, material/component composition, manufacturing location | Data organised in life cycle stages (design, manufacturing, construction, use, end of life) Manufacturing stage: Physical and technical, manufacturer, health and safety, warranty, EPDs/sustainability, reuse, end-of-life, carbon, maintenance guidance, % recycled, reused, bio-based content, material compositions, subproducts composition, subproducts passports, manufacturing location, classification, datasheets, standards compliance, green certificates compliance All other stages: Classification, geometry, design-related circularity information (designed for deconstruction, connect types, accessibility to connections), contractor information, installation information, condition, remaining lifespan, audits, deconstructino strategy, actual end of life |

| Ownership | Manufacturers own their material/component/product passports; architects or main contractors own system passports; asset owners own building passports | The entity that creates the passport – or who it is transferred to at completion | Data generated by users is owned by the users or the entity to which ownership is transferred |

| Intended users | Developers and asset owners (read), design or project teams (read), contractors (read), manufacturers or material suppliers (read/write), facilities managers (read), PDA auditors (read) | Developers and asset owners, design or project teams, contractors, manufacturers or material suppliers, facilities managers, local authorities | Developers and asset owners (edit/read), design or project teams (edit/read), contractors (edit/read), manufacturers or materials suppliers (edit/read), facilities managers (edit/read), PDA auditors (edit/read) |

| Business model | Digital Product Passports: free and unlimited access, Building Passports: subscription per project or per portfolio/year | Annual licence to use the platform; there are additional (lower) annual costs to store the data over the building’s lifetime; users can also buy additional support; product passports: from free | Digital Product Passport free to create & share for Manufacturers, Building Passports: subscription based on number of users, number of projects, scope of projects |

| Passport levels provided | Material/component/product via a digital product passport, system via a local or generic passport, building via a digital building passport | Building (asset) and product/material/component; can be ‘nested’ using a bill of materials | Product, Building (including whole building, element categories, systems, elements, bill of materials, and bill of products); portfolio passports; area passport |

| Building-level insights | Location within the building, quantity of prducts within a building; at deposed level: state of wear, degree of demountability, availability data, reuse potential, source (new or reused); at building level: inflow ESG indicators like embodied carbon, carbon intensity (scope 3), non-toxicity rate, circularity & reuse rate, recycled/biobased rate, demountability rate, economic residual value | Insights are aggregated from individual products and materials to the whole building (and portfolio if desired); insights include mass, circularity attributes such as recycled rate, reused rate, renewable rate, % able to be recovered for reuse/recycling, circularity score, detachability score, whole life carbon, etc; can show all insights at the whole building, split by shearing level or by material/product; where 3D information is provided, can project a heatmap of the results onto the 3D model; with BIM, full data and info can be accessed through a 3D viewer | By combining data from Products and BIM (or bill of materials) Building Passport provides automated performance insights & intelligence on different levels. Examples include % recycled, reused, biobased ontent, % new, existing reused, remanufactured, % can be dissassembled, reused, supported by take back scheme, no. of products with EPDs, carbon and other Building Passport includes: 3D Model viewer with Materials Passports Data and BIM data, Whole Building Dashboard, Building Elements Categorites Dashboard, Element Level Passports for each instance, Bill of Products, Bill of Materials |

| Interoperability with other digital tools | BIM tools, digital twins, and portfolio tools | Can import information from BIM; can perform an LCA calculation and send data to other digital twin systems or reuse hubs via an API | Can import from BIM, APIs, Excel and export to various applications including BIM, digital twins, facility management systems, and reuse hubs via API and/or Excel |

| Classification systems | RICS, LCBI and RE2020 categorisation, Unique passport number | Can use a range of classification systems including Uniclass, Omniclass, RICS WLCA, NRM and the Shearing layers; can store unique identifiers in the form of GTINs and provide unique identifiers within the system. QR codes can be generated at a product or asset level. | Uniclass classification (products, systems, materials); RICS classification (alignment with BREEAM, GLA, costing); project-specific classification; unique identifier for each product passport, element passport, building passport; QR code for each product passport, element passport, building passport; GS1 – GTIN for products; Products Categories Classification (in line with the EU Harmonised Standards) |

| Additional services | Passport system comes along with a holistic platform that provides the following functionalities: EPD generation platform, product selection platform, LCA calculation for concept design, LCA calculation for buildings, LCA calculation as built, material reuse platform, PDA tool, Brokerage services, LCA calculation for reuse materials, resource management during the operation phase, portfolio management, meta-marketpalce, urban mine management (with City of London) | Can deliver material passports, LCA calculations at all stages, can connect to reuse platforms; offer ‘track & trace; for manufacturers so they can see where their products are in use and when they are likely to become available again | Platform offers a Data PowerStation with a suite for end-to-end life cycle data management. Key integrated functionalities include: LCA Calculations for products (remanufactured, reused, industry averages, composite products), Product Specification Platform, LCA Calculations for Buildings (generic data, EPD-specific), Pre-demolition Audits, Portfolio Management, Internal Marketplace (available resources for reuse – within organisations), data links with external marketplaces |

| Stage of development | Beyond Technology Readiness Level (TRL) 9, meaning the platform has been fully developed, validated in operational environments, and is commercially available | Beyond Technology Readiness Level (TRL) 9, meaning the platform has been fully developed, validated in operational environments, and is commercially available | Beyond Technology Readiness Level (TRL) 9, meaning the platform has been fully developed, validated in operational environments, and is commercially available |

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Material Passport Platform

Online registry of materials used in buildings

Database of sustainable building products

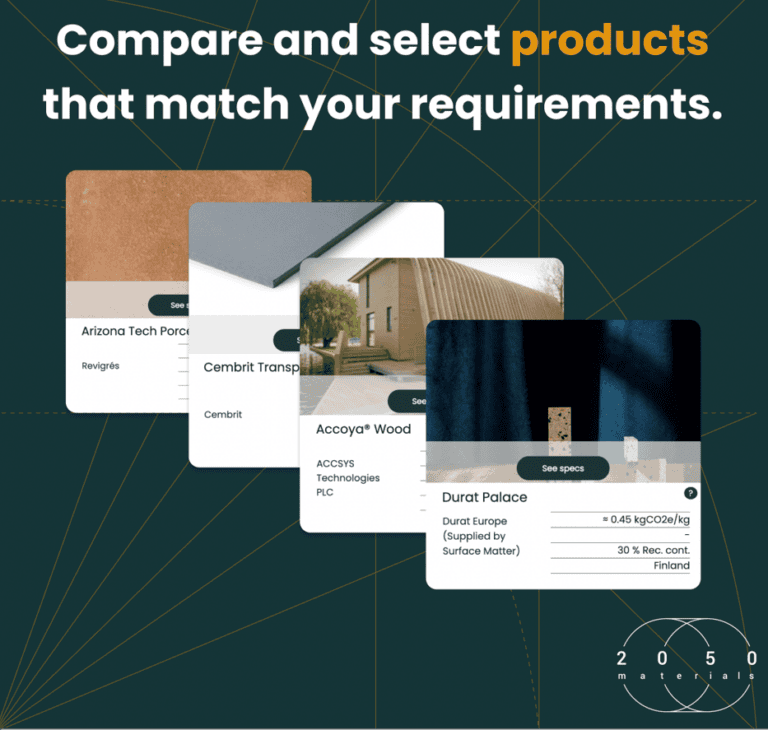

Product selection platform