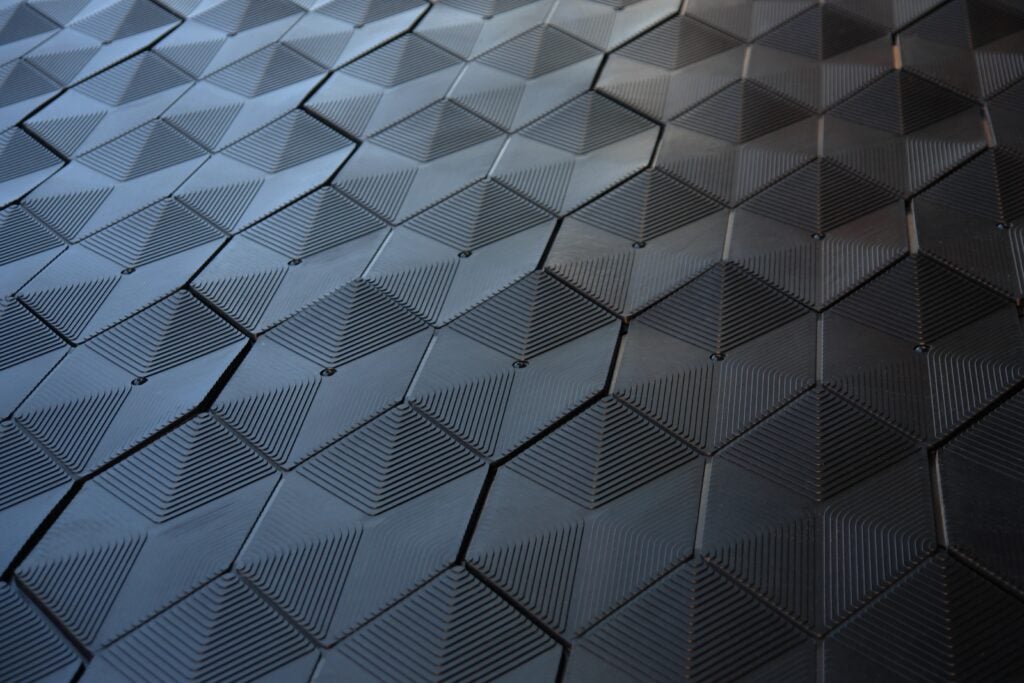

Facade panels made from non-food biowaste

Problem Addressed

The United Nations’ Intergovernmental Panel on Climate Change has stated that lifestyle changes alone will not be sufficient to mitigate the worst effects of climate change and has called for radical action to streamline carbon capture and storage methods. This climate change ‘reversal’ through CO2 sequestration will only work through the manufacture of significant volumes of materials that can act as carbon sinks. Scaling up this solution is another key challenge.

Case Study

Audi’s car dealership in Trudering, Bavaria

Made of Air provided 7 tonnes of material for a 700 sq. m. application of a rainscreen panelling.

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Modified wood for stability and durability

Zero cement concrete

Cement alternatives

Insulation boards made from meadow grass