Qube Buildings

Problem addressed

With embodied carbon responsible for 20% of UK built environment emissions, it is imperative that construction materials are as sustainably sourced and reusable as possible. According to the official UK Statistics on Waste, construction and demolition annually produce around 60 million tonnes of non-hazardous construction and demolition waste.

Modular construction systems such as structural insulated panels (SIP) present a way forward for reducing waste during the construction phase. Additionally, these systems are often assembled with design for deconstruction (DfD) principles in mind.

Overview of start-up

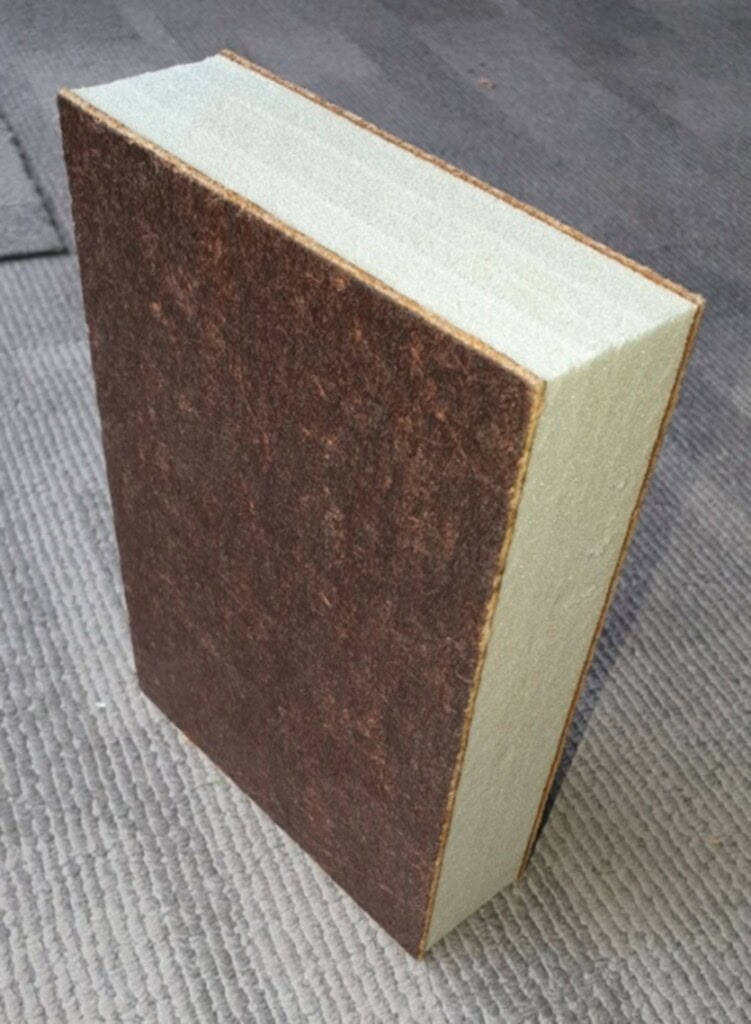

Bio-SIP™ is a sustainably sourced and high-performance SIP developed by Qube Buildings to make construction easier and more environmentally friendly. The panels themselves are composed of an insulation core made from 100% recycled PET plastic sourced from a reputable manufacturer, and a structural facing made from bio-based materials including low-carbon hemp and waste products from sugarcane production. In total, the Bio-SIP™ is made from 99.5% recycled plastic and organic materials. While this does create a wall system that combines the biological and technical cycles, the Bio-SIP™ is assembled without adhesives, allowing for easier disassembly. This means these components can be moved and reassembled or repurposed at end of life. By constructing the panels offsite, transportation costs and emissions are reduced, and assembly can be faster.

Energy efficiency is another benefit of the Bio-SIP™ system, as they have good thermal performance, aiming to achieve Passivhaus standards, reducing the energy needed to heat and cool a building. Bio-SIP™ is currently undergoing BBA and BRE certifications and has undergone successful initial fire testing.

What makes the start-up innovative?

Combining insulation, weatherproofing, and structure into a singular component, Bio-SIP™ offers an all-in-one solution for the construction of a wide variety of buildings including homes, bike shelters, cabins, glamping pods, and garden studios. Additionally, the combination of materials used is also innovative.

How the start-up has been designed to scale-up quickly

The Bio-SIP™ has been developed for mass production with the goal of allowing customers to have whole buildings delivered right to their door. The panels come in a variety of sizes and thicknesses, allowing for different designs, and they are easy to transport.