EcoDuct Ltd

Problem addressed

The built environment relies on high energy consumption and products with high CO2 emissions. It is an industry in which rigorous new standards and higher consumer demands are emerging.

Overview of start-up

Ecoduct offers a reduction in use of high CO2 products; a reduction in energy consumption; an increased use of recycled material; and a reduction in site wastage.

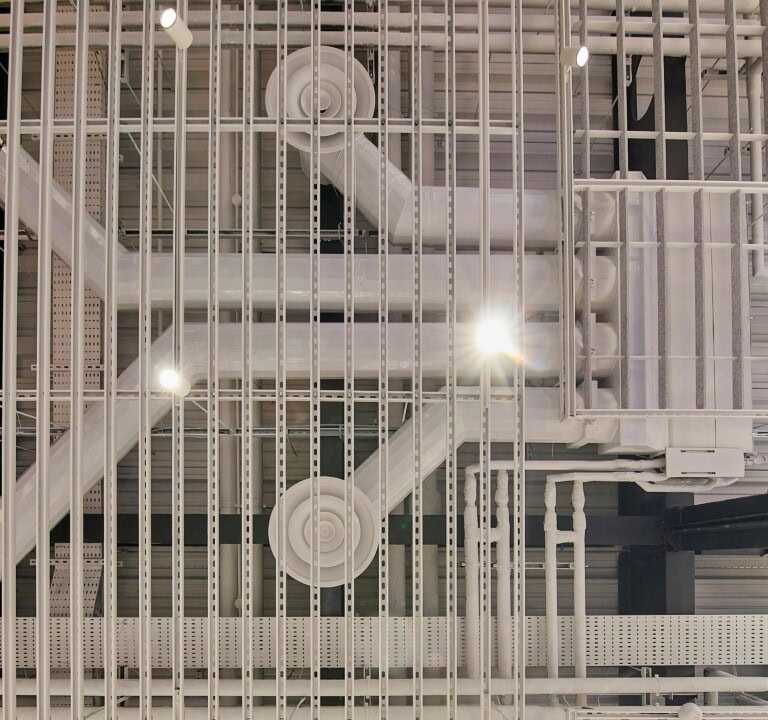

Ecoduct transforms ductwork from a concealed component into a design asset as it can be supplied in the shape, size, colour and effect required. Ecoduct offers pre-insulated non-metallic AC ductwork – circular, flat oval and rectangular, as well as FCU plenums and grille boxes.

Ecoduct’s pre-insulated non-metallic ductwork products have been developed with 3 clear objectives:

1. Improve the performance – airflow and thermal efficiency – of air delivery systems.

2. Reduce the CO2 footprint of HVAC systems (initial tests for the LCA indicate an unprecedented reduction of up to 75%).

3. Reduce the energy consumption of HVAC systems (initial tests show a saving of up to 45%).

What makes the start-up innovative

Ecoduct is the only company in the UK that manufactures and distributes all shapes and sizes of pre-insulated non-metallic AC ductwork. The current products are the result of 15 years of innovation, and new unique products continue to be developed.

How the start-up has been designed to scale-up quickly

Ecoduct has developed a production methodology, with machinery and production software, that will be replicated across the UK as demand requires.

Related Content

Sustainable pre-insulated air duct