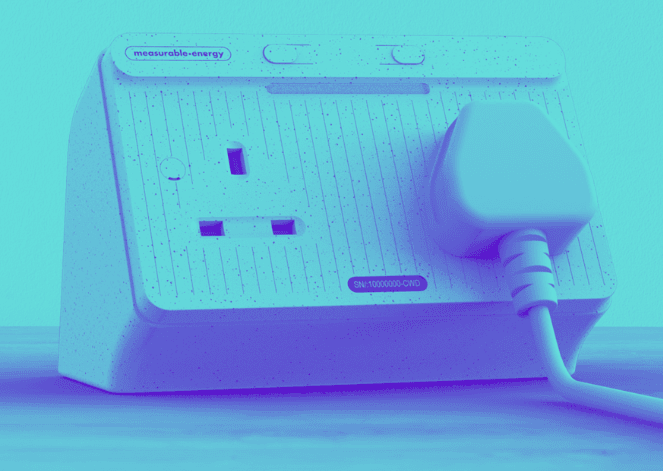

Smart fused spurs to reduce device energy use

Problem Addressed

With an average of 30% of energy purchased by organisations wasted, better ways to measure and reduce the energy consumption of a building’s devices are necessary to ensure energy purchased is effectively used.

Case Study

Kier Group, a construction and infrastructure services company, installed both measurable.energy’s plug sockets and fused spurs in their construction site accommodation, saving 59% in electricity bills with a 6-month payback. Several plug sockets and fused spurs were installed across two of Kier’s accommodation buildings and began collecting baseline energy and carbon emissions data. measurable.energy’s technology reduced energy use by 59% and CO2 emissions by 40%. A faulty heater was also identified using the technology, which Kier Group could uninstall before it became a fire risk.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related members

Related

A smart socket to reduce emissions

Tech to help organisations manage their sustainability goals.

Improved monitoring and collaboration for property teams

Commercial building energy optimisation