Unusual Rigging

Key sustainability objectives and outcomes

Resource Use and Circular Economy

The entire building is a testbed in testing circular economy design principles. Without defined circular economy industry standards or accreditations to work towards, it was necessary for the client and design team to set their own standards and goals based on the GLA’s 6 core principles of Building in Layers, Designing out Waste, Building for Disassembly, Building for Longevity, Building for Adaptability and Use of Re-Used materials.

Key circularity approaches included a layered construction strategy allowing each part – whether structural, service-related, or internal – to have a different expected lifespan and enable easy separation for maintenance, upgrades, or future reuse without damaging the surrounding fabric.

Reused materials were prioritised, including reused steel, raised access flooring and parts of the external landscaping. Internal finishes have been chosen and assembled with a focus on Circular Economy. Cradle-to-Cradle carpet tiles feature in the main office floors. Engineered cork flooring, made from off-cuts from the wine cork industry, features in the central circulation spaces.

Materials were selected to enable disassembly and onward reuse, helping to lower the building’s carbon footprint throughout its lifecycle. To support with this a modular frame was used to enable flexibility and future proofing. Bolted connections were used on the entire frame, cladding was mechanically fixed, flooring was fixed with non-adhesive substrate and window details enable easy removal.

Further, design for longevity has also been considered, through a flexible layout and the use of durable materials. This includes Accoya cladding with a 50 year warranty and a durable Kalzip roof. Connection details are also robust, with a concrete slab to protect the timber structure.

The construction approach also minimised waste, through the use of prefabricated wall and roof systems. There is also an operational waste management plan in place.

Operational Energy Performance

The energy use intensity of the building is 39.44 kWh/m2/yr, which exceeds LETI and RIBA 2030 target requirement of 55kWh/m2/yr. It is also EPC A+.

To achieve this, key measures include taking a fabric-first approach for thermal efficiency. Prefabricated timber framed SIP wall panels were used, highly insulated with recycled glasswool and lined with airtight OSB. This approached ensures quality to the thermal envelope seeking to minimise the performance gap. The U-values of the walls are 0.15 W/m2K and the roof was 1.12 W/m2K and all windows are triple glazed.

This approach of thinking beyond the standards provides a building which is net positive for operational energy in the summer months and already meets LETI 2030 standards.

Renewable Energy

Renewable energy is supplied by rooftop solar panels which powers an air source heat pump, providing all of the building’s energy in the summer.

Embodied Carbon

Although a whole-building WLC assessment wasn’t done in accordance with RICS, individual savings were calculated based on specific measures. A low carbon concrete, by Hanson (now Heidelberg) was used in the substructure saving 18.9 tonnes of CO2. A primary timber glulam frame was also used, allowing long spans to ensure the future flexibility of the internal spaces, without the high embodied carbon of steel or concrete.

Reused material choices also contribute significantly to carbon savings, including savings of 19.9 tonnes of CO2 from reused steel, 21 and 0.9 tonnes of CO2 from reused raised access floors. Additionally, the use of biogenic materials allows the building to store approximately 94.5 tonnes of CO2.

Further, the building was also a testbed for the use Adaptavate’s Breathaboard, a natural compostable alternative to gypsum plasterboard.

Social Value

The design not only prioritises the clients but employees and visitors as well by incorporating features that support comfort, focus, and connection. Elements such as dedicated tech-free areas, quiet zones for focused work, and the inclusion of greenery both inside and outside the building are all designed to support and enhance user wellbeing. Shared spaces such as reception, corridors, and breakout areas were intentionally arranged to foster interaction and a sense of community. Accessibility and inclusivity were built into every aspect of the layout, with thoughtful details such as the internal staircase and mezzanine designed to aid navigation, particularly for those with cognitive or spatial challenges. A mix of outdoor settings, including dining terraces and contemplative areas by an ecological pond and a memorial tree honouring founder Alan Jacobi, further enhances the user experience, offering places for relaxation, reflection, and connection to nature.

Lessons learnt

A primary obstacle was balancing the client’s environmental aspirations with the practicalities of cost, availability of materials, and construction methods. Sourcing reused or sustainably certified materials required meticulous planning and innovative solutions. Additionally, the evolving nature of circular economy practices posed difficulties in implementing concepts not yet widely adopted or supported by traditional supply chains.

Another challenge was integrating cutting-edge sustainable technologies, such as air source heat pumps and photovoltaics, into the building while maintaining a tight operational carbon footprint.

Related

Framework for a Nature-Positive Built Environment

Embodied Carbon Summit Evidence Report

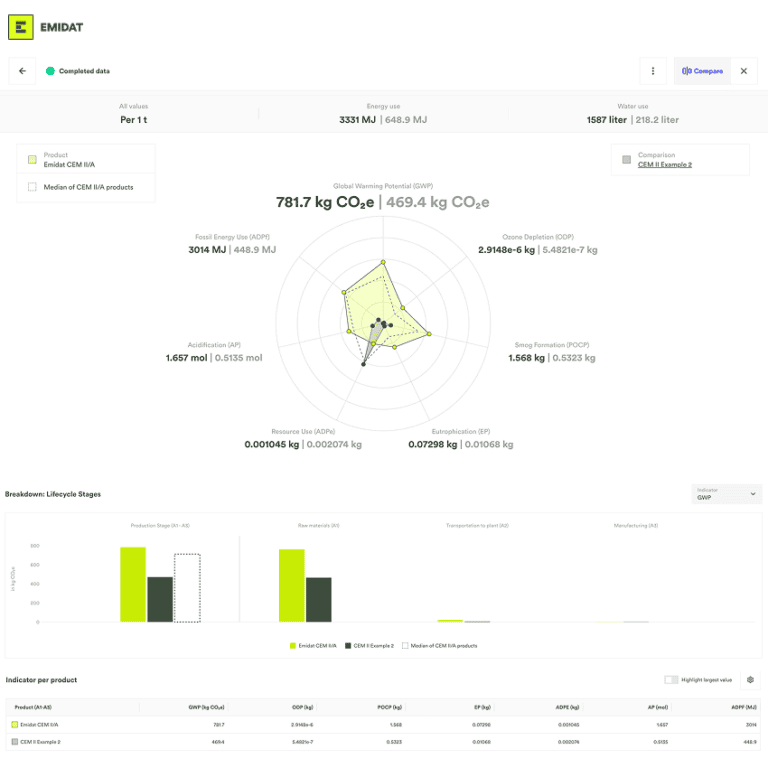

Fast, Pre-Verified Environmental Product Data

Trends in Sustainable Solutions 2025