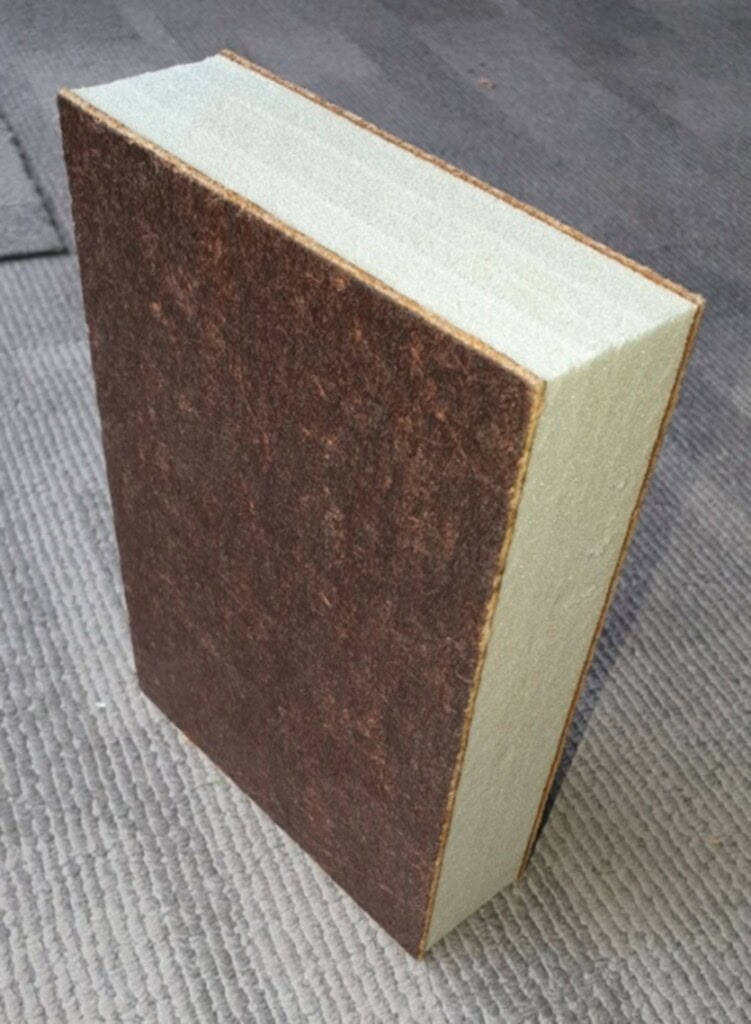

Sustainable Structural Insulated Panels

Problem Addressed

Bio-SIP™ addresses one of construction’s most pressing sustainability challenges – the environmental impact of traditional building materials.

With embodied carbon responsible for 20% of UK built environment emissions, it is imperative that construction materials are as sustainably sourced and reusable as possible. Some conventional insulation and structural systems rely heavily on carbon-intensive products such as concrete, steel, and petrochemical foams, which contribute to global CO₂ emissions and resource depletion. The industry also faces growing pressure to reduce waste and transition toward circular, low-impact materials without compromising performance or scalability.

Case Study

Bio-SIPS were used for the construction of a garden building in Chiddingfold, Surrey. Due to the modular components used, the entire building arrived flat-packed on a single luton van. A team of three installers completed the whole project in only two days including the installation of ground screws as a foundation system. The finished garden building was used to store paints and chemicals, meaning the thermal stability provided by the panels was appreciated by the clients.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Insulation boards made from meadow grass

Mycelium insulation

Bio-based modular wall system made of timber and straw

Affordable, low carbon modular homes