Insulating render / plaster

Problem Addressed

How to increase the thermal efficiency of walls and floors in older buildings without adversely affecting moisture levels.

Case Study

ProofTherm was used to insulate the external walls of a Victorian property in London in October 2020. By February 2021 the owner had measured a 20% reduction in relative humidity in the lower ground floor area as the breathable nature of ProofTherm allowed the bricks to dry out once the existing sand and cement render was removed.

As the lower ground floor area was electrically heated and metered independently from the rest of the property, a recorded reduction in electricity use of 22% across the equivalent period and with the same occupation and usage patterns can be largely attributed to the increased insulation values of the walls.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

Insulation boards made from meadow grass

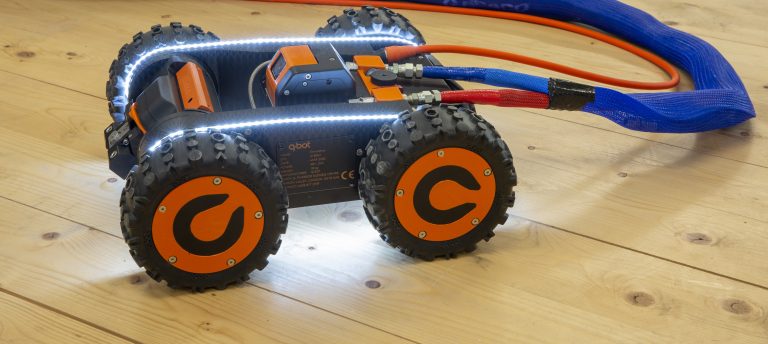

Robotic installation of underfloor insulation

Simple and efficient underfloor heating system

Project Etopia