Mycelium insulation

Problem addressed

Construction materials emit massive amounts of carbon long before the lights of a building are even switched on. In fact, 11% of worldwide carbon emissions come from their manufacturing (World GBC). As a result, the legislative landscape in Europe is changing to impose stricter regulations on embodied carbon emissions. In the UK, from 2025, the current materials on the market will struggle to meet new legislation like the Future Homes Standard.

PUR/PIR, Polystyrene and Phenolic insulation materials are made out of plastic, they’re non-renewable and their manufacturing process has high energy consumption. A challenge is that the alternative sustainable products currently on the market are often not as affordable and high performing as their oil-based counterparts.

Case study

Currently in development.

Facts and Figures

This page presents data, evidence, and solutions that are provided by our partners and members and should therefore not be attributed to UKGBC. While we showcase these solutions for inspiration, to build consensus, and create momentum for climate action, UKGBC does not offer commercial endorsement of individual solutions. If you would like to quote something from this page, or more information, please contact our Communications team at media@ukgbc.org.

Related

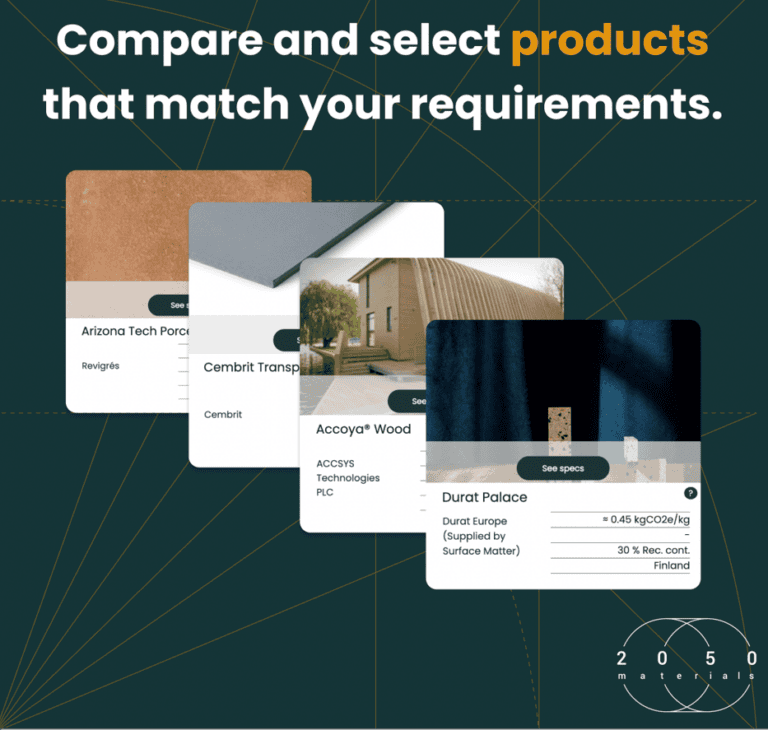

2050 Materials

Zero cement concrete

Cement alternatives

Bricks made from industrial waste